Oftentimes, it's easy to overlook the most significant hazards.

Oftentimes, it's easy to overlook the most significant hazards.

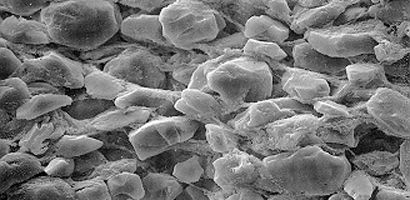

That's the case with crystalline silica, or silica dust. Silica dust is a known carcinogen that is easy to inhale. Unfortunately, this can lead to lung cancer and a host of other medical problems.

The new standard goes into effect on September 23rd. That date is approaching fast - but, don't worry, Medsafe is here to help. In this blog, we'll go over the new standards and provide some insight on whether your workplace safety program is up to speed.

Silica Dust: A Dangerous Workplace Contaminant

Crystalline silica occurs in nature. It is a component found in soil, granite, and many other substances. Though the substance exists in the natural environment, it becomes dangerous when inhaled. Once crystalline silica gets into the respiratory system, it can damage the lungs.

So, how is silica dust created? Cutting, grinding, or manipulating objects that contain silica is the cause. This leaves workers in certain industries at an elevated risk. One example of workers who face a greater risk are building contractors, as they often have repeated exposure to the substance due to the job tasks they carry out on a day-to-day basis. These tasks include things such as cutting bathroom and kitchen countertops out of slabs of granite.

Contractors aren’t the only workers who can face a high level of exposure. Others who need to exercise caution include:

- Well diggers.

- Those who work with concrete.

- Workers responsible for jackhammering.

- Those whose jobs involve demolishing old roads and bridges.

As mentioned above, the primary danger with silica dust is its carcinogenicity. Those exposed to high levels of silica dust are more likely to receive a lung cancer diagnosis. Of course, this assumes that all other risk factors are equal. Compared to other common forms of cancer, these lung cancer diagnoses come at a young age.

Silicosis: A Debilitating Consequence of Silica Dust Exposure

It's clear that exposure to silica dust correlates to lung cancer in workers. It would be bad enough if lung cancer was the only risk of this substance, but, it's not the only health hazard workers face.

Another hazardous, even fatal, risk of silica dust is silicosis. Silicosis is a condition marked by inflammation and scar tissue in the lungs. This scar tissue makes it difficult for the lungs to perform their normal function. Because of this, lungs can't take in the amount of oxygen required. Silicosis also makes the sufferer more susceptible to other lung infections, like tuberculosis.

The severity of silicosis depends on the amount and length of the exposure to silica dust. Exposure to large amounts of the substance could lead to acute silicosis in a matter of months. A low level of exposure could lead to chronic silicosis over the course of 15 to 20 years.

But no matter the diagnosis, silicosis reduces the worker's quality of life. The condition leads to shortness of breath and fatigue. This makes it much harder for workers to enjoy day-to-day activities, and could even prevent them from taking part in more physical tasks altogether.

At the moment, there's little that can reverse these effects. Some new drugs have shown some promise with relieving breathing challenges, but we do not yet have a treatment that reverses silicosis or stops its progression. Since there is no cure, we need to focus our efforts on limiting exposure to silica dust. This is the best way to prevent the numbers of those affected from climbing even higher.

OSHA Launches Its New Standards

OSHA recognizes the severity of these health challenges and have moved forward with aggressive new standards that will reduce the acceptable level of occupational exposure to crystalline silica.

OSHA's most recent estimates are alarming. They state that around 2.3 million American workers face silica dust exposure at work. The vast majority of these workers belong to the construction industry, and more than 600 of these workers die each year due to conditions associated with silica.

The biggest killers are pulmonary issues such as lung cancer and silicosis, but medical experts warn of other effects of inhaling silica dust. It puts tremendous pressure on the kidneys, which can lead to various kidney diseases.

The costs of treating these diseases continues to increase each year, but experts allude to money-saving news. The new, stricter OSHA silica standards have a cost-effective benefit, as they will lead to a dramatic reduction in medical treatment costs. OSHA places the prospective savings at approximately $7.5 billion each year.

How Do The New Standards Differ from the Existing Ones?

The potential risks associated with silica dust were clear as early as the 1930s. But, there had been no industry standards to limit workers' exposure until 1971. That year, OSHA put in place new regulations. They capped the amount of silica dust that could exist in different air samples. At the same time, they encouraged workplaces to institute protective programs. These programs would limit the presence of airborne silica.

The initial permissible exposure limits were set at 100 micrograms per cubic meter of air. Industry experts now recognize that these levels are still far too high. They still leave workers susceptible to debilitating health problems. More recent research better highlights how dangerous silica is to the human body. Also, it is now clear that silica-related damage can be irreversible.

Recognizing this, the new standard reduces the allowable level of silica dust by half. Workplaces must now reduce the contaminant to 50 micrograms per cubic meter.

And the new standards don't stop there. They also stipulate that employers need to use engineering controls to limit exposure. These controls can include either water or vacuum-based technology.

The majority of workers affected are in the construction industry. Because of this, OSHA has fast-tracked the regulations for companies in this sector. Construction companies only have until September 23rd of this year to update their practices. Other industries will have longer to get themselves up to speed. The extra time will help them better adjust to the new standards for compliance. These industries include those in the maritime sector and hydraulic fracking.

What other hazard exist on construction sites? Find out in our informative blog, "Outdoor Hazards on Construction Sites"

OSHA recognizes that businesses may struggle implementing the new regulations. They may find it hard to put new safety programs in place that would meet the stricter standards. That's why they're extending a helping hand to businesses and others who may struggle. The ultimate goal is not to punish companies with difficulty meeting the new limit. It's to ensure that workers remain safe and healthy across the course of their careers.

Conclusion: Stay Informed

We've all heard time and time again that knowledge is power. That is definitely true when it comes to the risks associated with silica dust. Keep up with the latest changes in silica regulations. CLICK HERE for a comprehensive update on the Silica Standard from 3M, and follow industry leaders like 3M and Medsafe to stay up-to-date on the newest control methods and technologies. This will empower you to take all the steps you need to protect your workers and their health.

If you're in the construction industry, the new standards are right around the corner. You should already putting measures in place to ensure that you remain compliant. But if you're not, there's no reason to wait until the very last minute. Start doing what you can now to reduce your workers' exposure to silica dust before the damage occurs.