While data specifically related to foot punctures is not available, the Bureau of Labor Statistics recorded over 94,000 cut, laceration, and puncture injuries in 2014 - resulting in an average of 3 days in lost work time per incident. The number of foot injuries in the same year stood at 52,000 - with an average of 9 lost work days per incident. Aside from the obvious revenue loss associated with lost time events; the cost of injury treatment, worker’s compensation, and potential legal settlements far exceeds the cost of investing in footwear designed to protect the wearer from puncture hazards.

Puncture Resistant Midsoles

A Puncture Resistant (PR) midsole is a Steel or Woven Fabric midsole that runs the full length of the shoe. It is designed to protect from sharp objects penetrating the foot if stepped on. Puncture Resistance is just that however - Resistance; as opposed to Puncture Proof. Sharp objects may still penetrate the PR midsole if there is enough compression on the object beneath the shoe (jumping from a high spot and landing on a nail, for example).

PR midsoles are manufactured from either Steel or a Woven Fabric. The two primary materials used for protective midsoles are Steel, and Aramid (woven fabrics with high tenacity; eg. Kevlar®, or Twaron®) The midsoles are embedded during the manufacturing process, between the insole and outsole of the puncture resistant boots. The standard that regulates puncture resistance specifies that the protective midsole of puncture resistant boots cannot be removed without damaging or destroying the boot. This means that effective puncture resistance cannot consistently be attained through means of a removable insert.

Puncture resistant boots incorporating a woven fabrics midsole are most likely to have a composite toe cap as well, to create a metal-free, lightweight work boot. This can be a critical element on sites where metal detectors are used as persons enter and leave, such as high-security environments, airports, government buildings and military bases; anywhere that scanning is used to prevent dangerous items from being concealed.

The Differences between Steel & Woven Fabric Midsoles

| Steel Midsoles | Woven Fabric Midsoles |

| Made from coated steel or stainless steel | Made from Aramid fibers like Kevlar® or Twaron® |

| More economic compared to textile/Aramid materials | More flexible compared to steel midsoles |

| Thinner than textile/Aramid midsoles | Lighter than steel midsoles |

| Embedded in the outsole construction, not visible when taking out the comfort insole | Sewn on to puncture resistant boots upper construction, visible when removing the comfort insole |

| Conduct cold, heat and electricity | Do not conduct cold, heat and electricity |

| Provide protection against very sharp and tiny objects | Recommended for people working in metal scanning environments |

| Less flexible than textile midsoles | More comfortable through the use of thinner, more lightweight materials |

| Do not protect the entire bottom surface of the footwear (a few millimeters stay unprotected on the sides) | Protects the full bottom surface of the shoe |

| Coated carbon steel is subject to corrosion after a period of time, especially at the flexline area | Combined very high strength-to-weight properties, with excellent temperature, abrasion and cut resistance values |

ASTM F2413

Although OSHA dictates the use of PPE, ASTM International is the organization that sets the performance requirements for protective footwear in the United States. ASTM International is a leader in developing and publishing technical standards for a wide range of products and is recognized globally as a dominant and respected standards organization. It is a requisite for safety footwear in the United States to comply with ASTM.

ASTM International standards set forth minimum requirements for the performance of footwear to provide protection against a variety of workplace hazards. Per the ASTM standard:

"Puncture Resistant (PR) footwear must also meet the Class 75 requirements for impact and compression resistant footwear.

The puncture resistant insole must withstand a puncture force of 270 lbs., will not crack after 1.5 million flexes and show no signs of corrosion when exposed to a 5% salt solution for 24 hours."

It is also worth noting that the Canadian (CSA) standard entails similar performance requirements, but requires that all PR footwear also meet their Grade 1 requirement for Impact Resistant footwear. The EN standard is similar, but slightly less stringent, and makes reference to PR insoles. Insertable insoles are not OSHA approved, and penetration of a sharp object through an insole of this type is considered an OSHA violation.

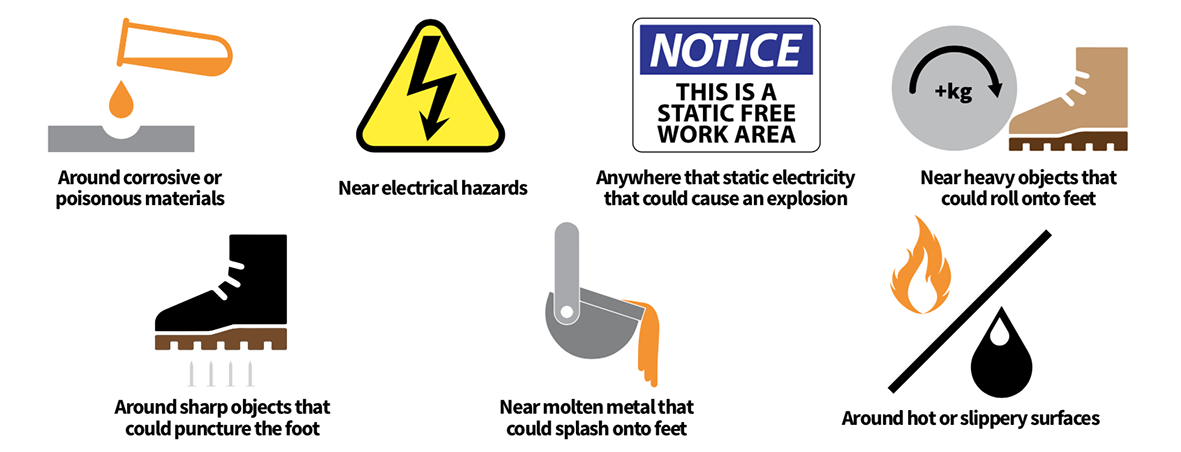

Protecting feet from punctures is only one hazard to consider when selecting and implementing safety footwear. Safety footwear is required in a variety of environments, and should be chosen only after a comprehensive risk assessment has been performed.

Important Considerations

Safety footwear, as with any PPE, should always be used as a last resort and should be chosen after a comprehensive risk assessment of potential dangers in the workplace. All other reasonable and practical measures should be taken to manage potential hazards, and Safety Footwear should be viewed as the final form of defense against hazards. Puncture Resistant footwear is becoming more of a standard requirement, especially in areas where sharp objects are prevalent. This is in addition to the more common dangers; those that are related to the kind of materials that are handled by the worker, risks of objects falling on or rolling over the feet, blades that might cut the top of the feet, or sharp objects that could penetrate the outsole of the shoe.

Medsafe carries a variety of Safety Footwear, including models that are manufactured with Puncture Resistant midsoles. CLICK HERE to visit the Medsafe website's Safety Footwear section.

The Medsafe PPE Guide is Now Available!

The guide covers six different categories of common PPE, and was created with YOU in mind. The guide has been designed to break down the process of PPE identification and selection, and make selecting products a more straightforward operation.

Each category addresses the relevant regulatory standards in place for both manufacturing and compliance, so you’ll know exactly what you need, and why you need it. We also outline the factors to consider when choosing a product, making the entire process less confusing. And finally, we provide links to relevant product categories at gosafe.com, so you can take a closer look, and even make your purchases online.

To download your copy of the Medsafe PPE Guide, click the link below: